Cutomized CNC Turning Rod Machining Lathe CNC Machining Parts

what is cnc machining?

CNC can be used to produce machining parts and prototypes very quickly with high precision, at a high production rate, the materials used are strong and durable for testing.

CNC machining is a subtraction manufacturing process that uses rotating computer-controlled cutting tools like drills, end mills, and turning tools to remove material from a solid block of material, thereby shaping the part.

Digital programming files direct the CNC machines how to cut the block (also known as the “workpiece”) and multiple machines can use the same programming file at the same time, which greatly increases the speed of the production process.

CNC machining is a viable option for manufacturing parts with a range of materials and surface finishes. Senze Precision is offering the full range of CNC milling processes, drilling, boring, countersinking, counter boring, tapping, reaming, wire EDM and EDM, plus more. We can rapidly produce your CNC machining parts with tight tolerances and excellent mechanical properties.

the advantages of cnc machining

1.Good quality, high accuracy and high productivity.

2.CNC machining service can produce the parts with complex structures.

3.Support various materials, including all kinds of metal material: aluminum, steel, brass, stainless steel, titanium alloy and plastic.

4.Small volume will be easier and faster for production, and better to control the quality and save cost.

5. It doesn't need to open mould, small quantity parts will don't have high mould fee.

Senze company specialized in high precision 3 4 5 axis CNC Machining parts hand mold OEM with high-end technology.

CNC machining includes turning and milling technical.

Milling

1. Machining square, rectangle, round+rectangle.

2. Used for processing planes, steps, grooves, gear teeth, threads, spline shafts, forming surfaces and cutting off workpieces, also process more complex profiles etc...

3. High efficiency, high precision.

4. It is widely used in machinery manufacturing and repair departments.

Lathe/Turning

1. Machining round parts.

2. Mainly uses a turning tool to turn a rotating workpiece.

3. Used for drills, reamers, reamers, taps, dies and knurling tools

4. High speed, high precision

We are good at

1.5/4/3 axis CNC machining

2.CNC turning machining.

3.Injection molding, Die cast molding

4.Sheet metal fabricate, laser cutting service.

5.Surface treatment

6.QC test system: VMS/CMM QC inspection

7.Certification We have:ISO9001:2015

Materials for cnc machining

Working process for cnc machining

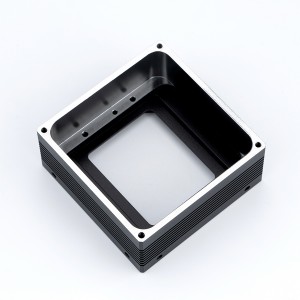

More parts photos for cnc machining parts

Company profile

SENZE CNC Machining OEM Factory

SENZE is located in No.104,4 Building,Jufeng Derong Industrial Park,Xiaobian Village,ChangAn Town,Dongguan City.It is a OEM CNC Machining and 3D printing supplier.Our customers cover Europe and America.SENZE specialized in high precision 3/4/5 axis CNC processing parts producing with high-end technology.

Equipment for cnc machining parts

1.Advance CNC lathes machining center

2.DMG 5 axis CNC machining center

3. 3/4 axis CNC machining center

4.EDM/WEDM Machines

5.Mold--plastics/steel mold service center

6.VMS+CMM QC test system.

Skilled workers for cnc machining parts

5 axis CNC machining workshop

4 axis CNC machining workshop

Strictly Quality Control System

SENZE has strictly quality control process, and also has imported CMM(Coordinate Measuring Machine), and VMS(Projector) in order to reach the quality standard of clients. Our customers trust us to supply right first time and they can rely on our highly experience team of engineers and timely delivery.

CNC Machining Parts